PAGE 8 OF 11

JULY 2012

Repeat above operations until entire area has been stripped.

Use machine, as indicated, to dry burnish area to give uniform

appearance.

Dust mop before applying first sealer.

HARD FLOORS

STRIPPING SYNTHETIC POLISHES (Continued)

Equipment to be checked before and after use and any damage to be reported to Supervisor.

Check that mop handle is smooth.

Do NOT leave mop lying on the floor.

Stand the mop upright in a corner when not in use.

Danger signs to be used where applicable.

Do NOT use rubber soled shoes as these are slippery on wet surfaces.

Equipment to be checked before and after use and any damage reported to Supervisor. Special attention to be paid to power leads and

machines.

Ensure room is well ventilated.

OH&S

Be aware of dangers of slipping when working.

Always use signage.

Power leads to be checked for fraying or exposed wires, and any defect to be reported to Supervisor.

Power leads to be kept behind machine at all times to prevent machine from cutting or damaging lead.

Watch your back for straining. If you feel your back straining, tell your Supervisor.

HARD FLOORS

APPLYING SYNTHETIC POLISHES

Danger signs to be posted (if applicable).

All furnishings and fittings to be removed.

All doors and windows to be opened.

Check to make sure floor has been properly stripped and burnished.

Do NOT apply polish to a dirty floor.

Remove all surface dust with dust mop.

Use sealer polish in accordance with manufacturers.

A thin, even, layer of polish to be laid around the perimeter of the area to be treated.

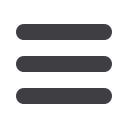

First coat of polish to be applied in parallel overlapping strokes as indicated, covering entire area. Thin even coats should be applied.

Allow polish to dry. Use fans to assist drying process if drying if drying is taking too long a time.

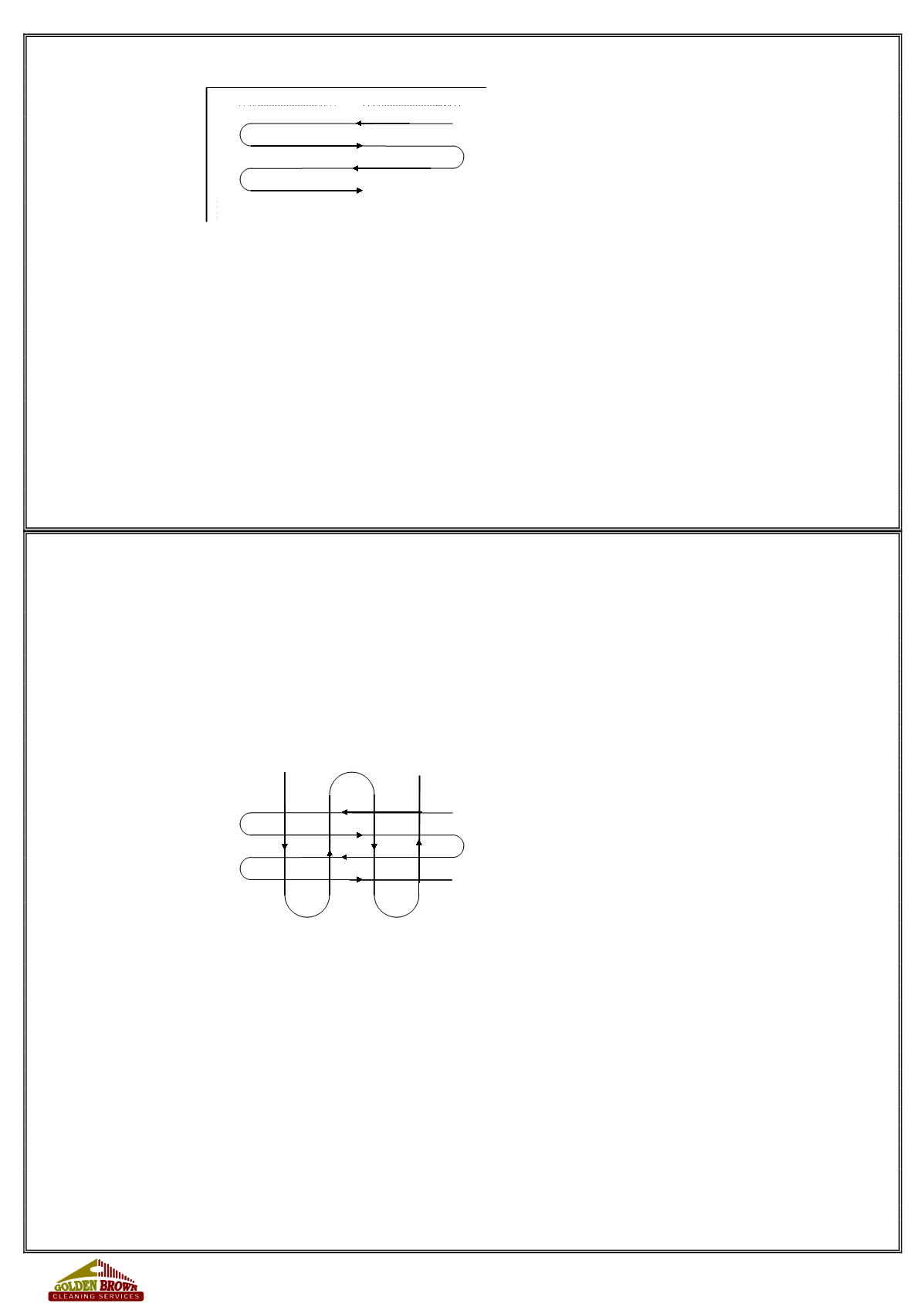

Second coat of polish to be laid at right angles to first coat as indicated:

When completely dry, buff with a fine pad or soft brush. Do NOT buff floors which are not completely dry.

HARD FLOORS

APPLYING SYNTHETIC POLISHES (Continued)

Dust mop the area.

Repeat buffing and dry mopping until desired finish has been achieved.

OH&S

Equipment to be checked before and after use and any damage or unsafe condition to be reported to

Supervisor.

Ensure room is well ventilated.

Do NOT smoke or allow naked flame or sparks.

Power leads to be checked for fraying or exposed wires, any defect to be reported to Supervisor.

Power leads to be kept behind machine at all times to prevent machine from cutting or damaging lead.

HARD FLOORS

STRIPPING SOLVENT WAX

It is preferable for stripping to be carried out on a dry day as this helps to ensure quicker drying.

Stripper solution to be made up in wringer bucket in accordance with manufacturers instructions (never to exceed instructions as this may cause

damage to floor).

COARSE HAND PAD

PERIMETERS

MACHINE PATTERN